Technical Facilities

As part of the University of Oxford, we can help companies access the facilities and know-how you need to successfully develop your technology. Specialist, cutting-edge facilities across the University can be accessed on a pay-per-use basis, and consultancies with research and technical staff can be brokered. Example facilities across the University include:

Electronics and mechanical design and prototyping

NMR Spectroscopy and Mass Spectrometry

Oxford University Innovation – Services Showcase

Oxford University Science Park itself hosts research groups from the University Departments of Engineering Science and Materials, with several specialist facilities located on site:

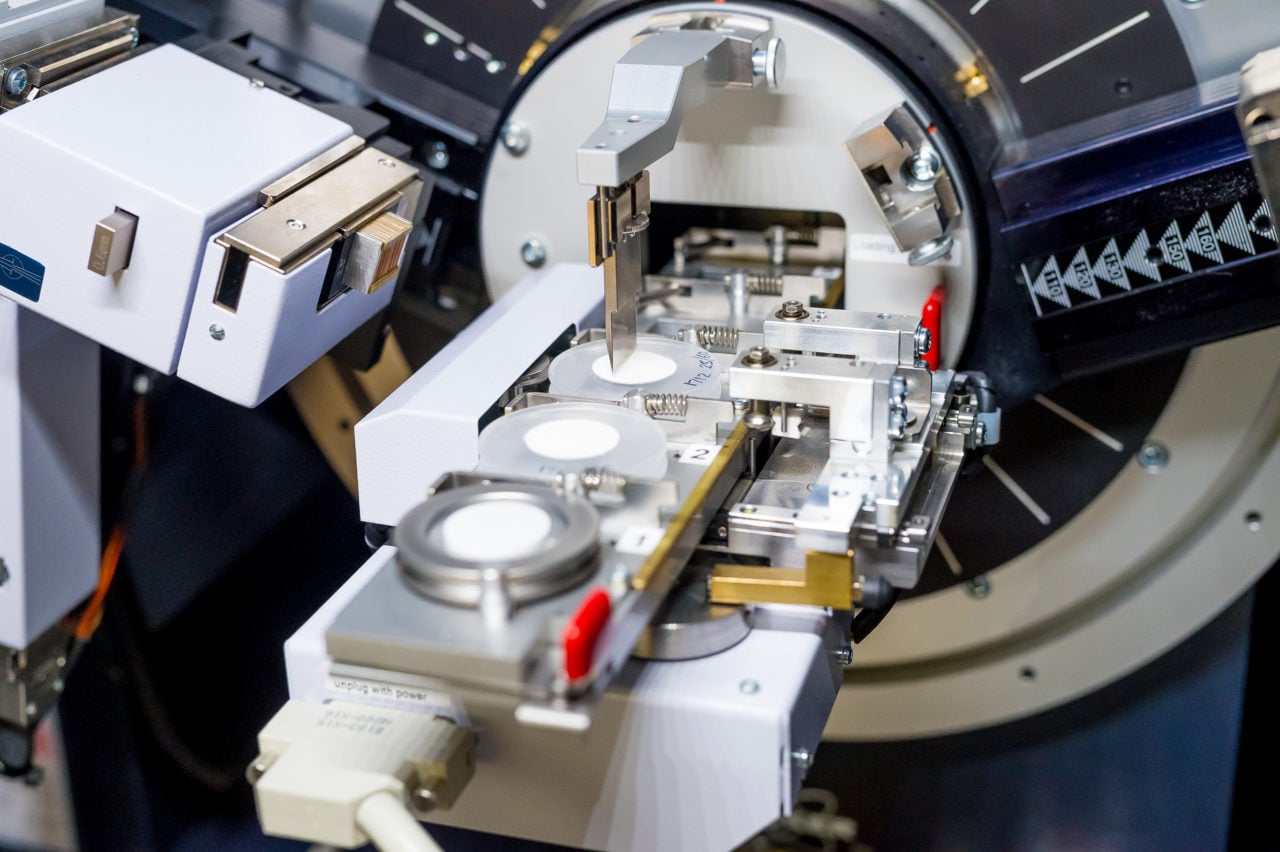

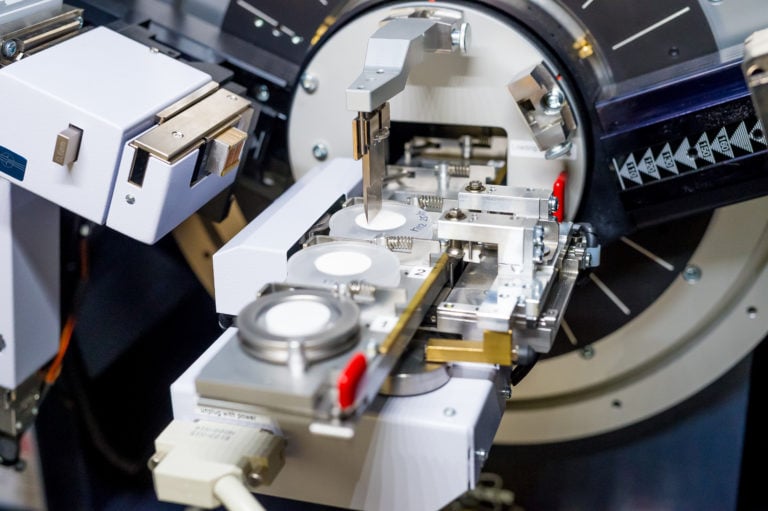

Oxford Materials Characterisation Service (OMCS):

Part of Oxford University’s Department of Materials, OMCS provides specialist services to industry, combining scientific expertise with a modern, well-maintained equipment base. OMCS customers span a wide variety of industry sectors such as energy, automotive, aerospace, electronics, biomedical, structural materials, ecology and forensic science. You can book time on equipment, call on problem-solving skills for help with materials development; and get quick, cost-effective, confidential materials analysis.

View the Site

Prototyping lab facilities:

Equipped with a range of 3D printers and software to allow you to design, prepare and 3D print, enabling high resolution scale up and production for your needs. The suite includes the following:

- Form 2: 3D printing (down to 25 μm) from liquid resin to hardened plastic using Low Force Stereolithography (LFS) ™ technology. Build volume of 14.5 × 14.5 × 18.5cm

- Ultimaker S5: Dual extrusion 3D printing (down to 20 μm) from a range of plastics/composites. Build volume of 33 x 24 x 30 cm

- Markforged Onyx: Carbon fibre 3D printing (100 μm) for Industrial grade parts. Build volume 32 x 13.2 x 15.4 cm

Nano Fabrication Cleanroom:

Providing 150m2 of space, class 10,000 with a suite of equipment, including e-beam evaporator, PECVD, photolithography

Visit the site

The Impact Engineering Laboratory:

Carrying out research in the aerospace, automotive and defence industries in areas such as high-velocity impact, crash worthiness and underwater explosion

Visit the site

The Advanced Materials Processing Laboratory:

Developing advanced materials and scale up processes for manufacturing in bespoke semi-industrial laboratories

Site Support Services

Our main reception will answer your phone calls, make your visitors welcome, and provide all the office services you need, including signing for deliveries and post,...

Space & Facilities

Here at Oxford University Begbroke Science Park, we provide an environment that helps innovative science & technology businesses through the difficult early stages of growth by...